Plastic, as a finishing material for ceilings, is now becoming more common. If we compare it with other types of ceiling trim, this method will cost more than materials and installation work used in other cases. However, the subsequent price of the actual operation of the plastic ceiling will be much lower.

Content:

The concept of plastic ceilings includes specific types of ceiling coatings - Armstrong, Grilyato and others. For them, specially designed installation scheme, suspension structures, assembled from the simplest bearing elements, plastic panels of various sizes and colors. There is a huge variety of instructions explaining the correctness and sequence of assembly of such ceilings.

Plastic after installation does not require any additional processing of the front surface. With even very strong soot and soot pollution from gas stoves in kitchens, plastic easily restores its original decorative qualities and color range. This is ensured by simple washing with plain water with soapy water.

PVC plastic is hygienic, under normal conditions it does not emit any chemical fumes harmful to humans, and is resistant to biological contamination in the form of rot, mold and fungal damage. Its destruction begins to occur at a temperature not lower than 120 degrees Celsius.

The use of plastic for finishing ceilings

Until recently, square or rectangular panels with deep relief of polystyrene based on expanded polystyrene (this is often used for the packaging of household appliances) were used to refine ceiling coatings.

The porous surface of these panels had low resistance to contamination in the form of dust, cobwebs, grease and soot, absorbed well and gave off such unpleasant odors as tobacco smoke to the surrounding space. Washing this lining did not give any effect, and the front surface was covered with non-removable dirty divorces. The only way to combat these troubles was to completely replace the ceiling.

Therefore, rectangular PVC plastic panels with dimensions of 0.25 x 3 m and a thickness of 7.5 ... 8.0 mm were most commonly used for ceiling systems. These panels, produced by the extrusion method, consist of two flat plates interconnected by longitudinal stiffening ribs, the distance between which does not exceed 1 cm.

Especially well seams are masked on panels with a glossy working surface, as well as with periodic patterns or ornaments applied on them. Even more invisible joints between the panels will become when they are installed perpendicular to the wall in which the window openings are located.

The location of the seams along the gaze, looking at the ceiling, visually makes the room longer, and across - wider.

In some cases, the seams are specially made visible, and they serve as one of the elements of the specially designed decor. PVC plastic panels with visible seams are called - lining.

Sometimes, continuous PVC sheets with a thickness of up to 5 mm are used for plastic cladding with a variety of colors or prints. These sheets, resembling very hard linoleum, can have a rectangular or square shape.

Ceiling PVC panels, unlike wall panels, are thinner, lighter and stronger.

The price of ceiling panels can be significantly lower than the wall. Very rarely plastic PVC panels are installed with glue. To select this method, you need a smoothly leveled, cleared of chalk and other colors of the substrate. Adhesive mastic should provide reliable adhesion between the glued planes.

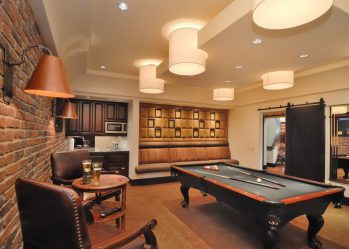

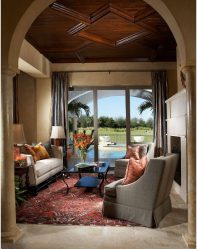

Plastic panels can be combined in color, pattern, combined with other types of ceiling decoration - plasterboard, decorative plaster, stretch fabric. PVC plastic can be used in the most daring vintage design projects in the design of residential and business premises. Increasingly, multilevel ceiling systems of a stepped design with elements of a straight or complex curvilinear shape with a luminaire device of the original form are being used.

Plastic panels well hide defective places and irregularities of wooden and concrete floors, various engineering communications. This may be the loss and delamination of the old plaster coating, ledges between the lower surfaces of adjacent reinforced concrete slabs.

Access to maintenance repairs is not difficult.

This most often may require the dismantling of one or more plastic panels, the subsequent return to the place of which seems to be quite a simple matter.

Illumination of rooms with plastic panel ceilings can be performed using built-in spotlights or in other ways agreed with the customer or the owner of the room. Sometimes, with a suitable height of the room, equipment for ventilation and air cooling is installed above the plastic level.

Facing

Facing is done in different ways:

- direct fastening panels on the ceiling;

- the use of intermediate guide rails, pre-exposed, aligned to the level and connected with the overlap;

- pre-assembling frameworks of wooden or metal parts and leveling them horizontally using the floor level is the best way to fit any ceiling.

Wooden frames are made from slats with dimensions of 50 x 20 mm. They are interconnected by corners, bent of tin, or wooden short stack with screws. Metal frames are the easiest to collect from stock bent galvanized tin profiles used for plasterboard.

The flat construction of the frame is pre-assembled with alignment on the floor, then, after posting, it is fixed in a horizontal plane using a water or bubble construction level. The frame is attached to the ceiling with nails or self-tapping screws.

To the frame panels are attached in a standard way.

For the manufacture of framework rails, it is necessary to take well-dried softwood - pine, larch. This will give the opportunity to avoid warping, distortions of the ceiling surface during its operation. Before installing the wooden frame, its elements must be protected with antiseptics from rotting and fire retardants against fire. There are special impregnations of deep penetration, combining these two most important for wood protection.

Self installation

The device of plastic ceilings with his own hands under the force of the performer who does not have any experience in the performance of such work. Independent lining of any type of plastic overlaps does not require a specially purchased tool. Screwdrivers, drills, hacksaws, hammers, levels and plumb lines are always at hand with any home craftsman. All materials traditionally used for this purpose are easily processed and adjusted to the desired dimensions.

- To install plastic, it is enough to familiarize yourself with the technology of work, study the recommended procedure for operations.

- Next, you need to prepare materials and bring your tool in working condition.

- In order to minimize the overrun, to limit the residues in the form of scraps, perform a preliminary calculation of the required amount of materials. This is done using concepts from the school geometry course. These include - width, length, height, methods for measuring the areas of flat figures, their addition and subtraction, the Pythagorean theorem of sines (cosines).

- Further from the executor of the work on facing and finishing the ceilings with plastic, only exact calculation and accuracy will be required.

Reliable step ladders and scaffolding must be claimed. At the time of work, it is recommended to invite an assistant who, in addition to providing services in the ancillary works, will be able to provide first aid if necessary during accidental mechanical injuries or electric shock.

return to menu ↑Application and operation

Plastic ceiling coverings can be used in residential and public areas. Since the purpose of such rooms are usually different, plastic ceilings in them may have their own characteristics. Let's look at these features in more detail. The aesthetic qualities of ceilings can be maintained in good condition for decades, it all depends on their care and regular maintenance.

It will be interesting to you:

Pros and cons of the stretch ceiling in the bathroom: The best solution or fashion? (125+ Photos)

The ceiling in the room (310 + Photo): high quality and fashionable. Only win-win options

Ceiling design: (+230 Photos) Modern stretch ceilings from A to Z

Ceiling plasterboard in the hall: 80+ Photos of this feast of design and luxury

Plastic ceiling in the kitchen

Kitchen the ceiling looks best from panels with a glossy surface. It is most easily cleaned from greasy soot from a gas oven, unlike panels with deep embossing or relief. The color or pattern can be chosen to match the ceramic used. tile, wallpaper or kitchen of furniture.

It is possible to restore the gloss by wiping the surface with a weak (1 ... 3%) solution of ammonia or ammonia. The process of cleaning from dirt can be organized with the help of an ordinary mop with a rag or using a washing vacuum cleaner.

return to menu ↑In the bathroom

Using plastic when installing the ceiling in bathroom room - one of the most progressive ways of finishing. The bathroom is designed to receive water treatments, and, therefore, is characterized by high humidity. Plastic PVC panels themselves are very resistant to water spray or high humidity.

The elements of wooden frames should be additionally protected with waterproof paints based on polymer resins - acrylic, epoxy, polyurethane.

Metal frames are best used with galvanized sheet metal parts. For better protection against corrosion, you can use a coating based on red lead or chromium oxide, diluted in natural drying oil. Good results are obtained by coating with bitumen or coal lacquer. It is better to isolate the gaps, gaps in the places of junction to the walls and engineering communications with polyurethane mounting foam or silicone mastic.

Installation, connection, insulation of electric lighting devices must be performed by an electrician who has certification. All switches, sockets are better to take out of the premises of the wine room. These actions will avoid electric shock during operation.

return to menu ↑In the corridor

Ceilings in the corridors as well hallways also often trim plastic panels. Instead of one lamp in the form of a chandelier, sconce or ceiling, several built-in spotlights are used. The device of the console of individual connection will allow to allocate separate zones or spaces indoors.

In the toilet room

Nothing better than plastic was designed for finishing the ceilings of insulated toilet rooms. PVC panels do not absorb and do not retain any odors for a long time, unlike plaster, drywall, fabrics. Plastic well hides a variety of ceiling piping engineering and other communications, as well as systems of normal operation of the building.

In houses built 30 ... 50s of the last century, you can still find toilets with vertical drain. In this case, the discharge pipe comes out of the ceiling of the toilet room of the lower floor and smashes into a sewer riser at a right angle. Alteration of this design requires the replacement of toilet bowls, sewers and reinforcement of floor decks. If this is not possible, such a construction can be hidden behind a suspended plastic ceiling.

On the glazed balconies and loggias

Plastic is widely used for interior glazing balconies and loggias. This gives such rooms a finished look, hiding the defects of brick or panel walls, as well as supporting balcony slabs.

return to menu ↑In the bedrooms

The installation of plastic ceilings in the bedrooms can be done in various ways. If the height of the room allows, it can be Armstrong or Grilyato type ceilings. They use a grid of standard profiles with shelves, creating a suspension system with cells of the desired size.

It looks interesting ceiling coverings of mirror plastic sheets.

Ceilings in sleeping rooms with a height of 2.20 ... 2.50 m can be made of the usual three-meter plastic panels on wooden or metal frames. As design solutions, you can alternate the order of colors and patterns of adjacent panels. They can be set, both in tone to the pattern of the neighboring sheets, and in the opposite-contrast version.

Like other finishing building materials, plastic, including in the form of PVC panels, for ceilings has its advantages and negative qualities.

How to make a ceiling?

Detailed instructions